Vacuum Division

Leading Manufacturers, Exporters and Wholesaler of Steam Jet Ejector Vacuum Systems, Steam Jet Air Ejector (SJAE), Steam Jet Thermocompressor, Steam Jet Vacuum System For Edible Oil Plant, Water Jet Ejector, Jet Venturi Fume Scrubber and Liquid Ring Vacuum Pump from Chennai.

| Business Type | Manufacturer, Exporter, Supplier |

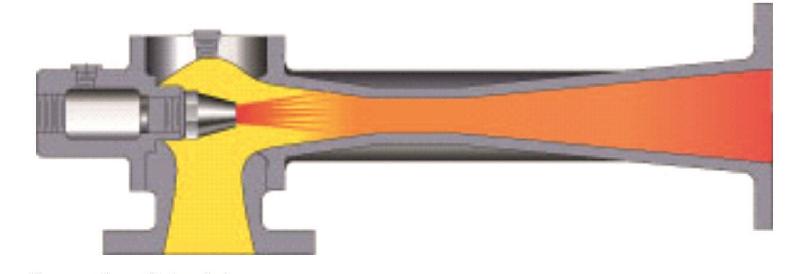

Single-Stage Steam Jet Ejectors are based on the ejector-venturi principle. In operation, steam issuing through an expanding nozzle has its pressure energy converted to velocity energy. A vacuum is created and the high velocity of steam entrains air or gas and the mixture of gas and steam enters the converging end of the venturi, passes through the diffuser where its velocity energy is converted into pressure sufficient to discharge against a predetermined back pressure.

Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute.

Two Stage Ejector with Condenser - The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type). Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser. The discharge from the first stage will then directed to condenser which reduces volume of discharge gases. These gases turn discharged with the help of second stage ejector. The ejector is required to be placed at sufficient height to drain the ejector condenser barometrically. If barometric installation is not possible then an extraction pump is provided to drain the condenser in vacuum. The discharge or exhaust steam and entrained gases is directed to the atmosphere or can be condensed by an after condenser or lead to a water tank if required.

Absolute Pressure Range: Vacuum from 100 MM HG Absolute to 10 MM HG Absolute.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Driven | Electric |

| Type | Twin Element Duplex Design |

| Usage | Maintaining Vacuum In Turbine Surface Condenser By Removing Non-condensable Gases And Water Vapor |

| Design Pressure For Electric Generation Service | 0.035 Ata (25.4 Mm Hg (a)) Or Lower Of Condenser Design Pressure |

| Design Pressure For Pumps, Compressors, And Mechanical Drives | Condenser Design Pressure Minus 0.035 Ata (25.4 Mm Hg (a)) |

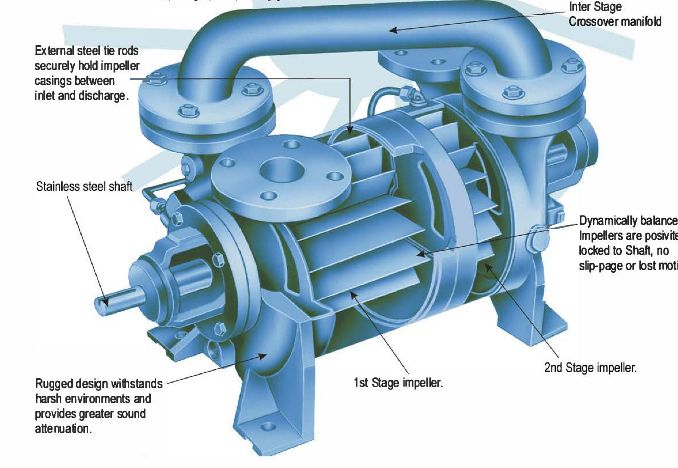

| Components | Hogger/Start-up Ejector With Silencer, Inter And After Condensers, Liquid Ring Vacuum Pump |

| Feature | Combination Units With Ejector And Surface Condenser Coupled Liquid Ring Vacuum Pump |

The efficiency of a Steam-turbine is mainly determined by the pressure of the steam at its outlet. The Turbine Surface Condenser is therefore maintained under vacuum. To enable this, the Steam Jet Ejector Vacuum System must be capable of removing all non condensable and associated water vapour from the Surface Condenser to produce the minimum steam condensing pressure consistent with physical dimensions and heat transfer and to provide for deaeration of the condensate.

The sources of non condensables include air leakage through all system components operating below atmospheric pressure, gases released from feedwater drains and vents admitted to the condenser, gases released for make-up admitted to the condenser, condensate surge tank when utilized in a closed cycle and disassociation of feedwater into oxygen, hydrogen and non condensables.

The recommended design pressure of the Steam Jet Air Ejector (SJAE) System is as follows :

- For electric generation service : The design pressure is 0.035 ata (25.4 mm Hg (a)) or the condenser design pressure whichever is lower.

- For Pumps, compressors and other mechanical drives : The design pressure is that for which the condenser is designed minus 0.035 ata (25.4 mm Hg (a)).

Usually, the SJAE system is of Twin Element type i.e. of duplex design having two identical Ejectors per stage, one of which, being in operation at any one time and the other as stand-by. The Inter and After Condensers are generally Single Element type.

The System also includes a Hogger / Start-up Ejector with Silencer for fast pre evacuation and which is in operation only till the desired vacuum has been achieved. Thereafter, the two stage holding ejectors take over.

In this field of application, combination units with Ejector and Surface Condenser coupled Liquid Ring Vacuum Pump are also becoming popular.

| Business Type | Manufacturer, Exporter, Supplier |

Large industrial plants often vent significant quantities of low-pressure steam to the atmosphere, wasting energy, water, and water-treatment chemicals. Recovery of the latent heat content of low-pressure steam reduces the boiler load, resulting in energy and fuel cost savings. Low-pressure steam's potential uses include driving evaporation and distillation processes, producing hot water, space heating, producing a vacuum, or chilling water. If the steam pressure is too low for the intended application, a steam jet thermocompressor can boost the pressure and temperature to the required level.

Operating Principles - Thermocompressors and ejectors operate on the same thermodynamic and physical principle: energy contained in high-pressure steam can be transferred to a lower pressure vapor or gas to produce a mixed discharge stream of intermediate pressure. These devices are known for :

- Simple construction

- Easy installation

- Long useful operating lives

- Insensitivity to fouling

- Low capital and installation costs

- Easy maintenance with no moving parts

If the objective is to recover the latent heat content of the low-pressure suction vapor for process use, the device is called a thermocompressor. If the objective is to pull a vacuum on a process vessel, the device is called an ejector.

Boosting Steam Pressure and Temperature with Thermocompressors-Single- or multi-stage thermocompressors are used to boost low-pressure vent steam to a useful higher pressure and temperature. When high-pressure motive steam is available, thermocompressors can be economically used for compression ratios up to 6:1 (absolute pressure of supply steam/suction steam).

High-pressure motive steam supplied to the thermocompressor expands in a converging-diverging nozzle to convert pressure energy to kinetic energy. Vent steam supplied to the suction port is entrained into this low-pressure/ high-velocity jet, where mixing occurs. The diffuser portion of the thermocompressor reconverts the kinetic energy of the mixture back into pressure. The intermediate discharge pressure is between the pressures of the motive and low-pressure suction steam. Discharge pressure is determined by the compression ratio (i.e. the ratio of the pounds per hour [1b/hr] of motive In steam supplied to the lb/hr of low-pressure suction steam entrained).

Thermocompressor capacity of the device is dictated by the availability of motive steam, motive and suction steam pressure, and discharge steam pressure requirements. Applications include drying and heating, multi-effect evaporators, vulcanizers, reboilers, strippers, condensate receiver tanks, and solvent extraction processes etc.

Applications :

- Check application of thermocompressors where significant venting of low-pressure steam occurs, higher-pressure motive steam is available, and a modest pressure boost could convert waste steam to useful steam. Examine waste recovery potential by determining.

- Flow rate and pressure of vented steam

- Flow rate and pressure for sources of motive steam

- Process or heating needs that can be met by boosting the pressure and temperature of vented steam

- Equipment size and motive to suction steam ratio

- Annual energy savings and installation costs of selected device

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Country of Origin | India |

| Driven | Electric |

| Type | Ejector Vacuum System |

| Application | Edible / Vegetable Oil Processing |

| Advantages | Total Absence Of Moving Parts, Constant And Dependable Operation, Simple Operation |

| Suitability | Deodorization Application |

Vacuum is necessary during various steps of edible / vegetable oil processing. These steps essentially include hydrogenation, fractionation, bleaching, deodorization and de-acidification. Out of all vacuum equipments, Ejector Vacuum System has established the superiority and versatility of their use as compared to mechanical vacuum pumps. The most outstanding advantage of the Steam Jet Ejector is total absence of moving parts which eliminate mechanical breakdown, and assures constant and dependable operation with freedom from repairs. No adjustment or lubrication is required nor are any specially trained operator necessary as their operation is very simple. Over and above, Steam Jet Vacuum System convey at very high velocity which are many times the speed of sound, they are capable f handling large volume under vacuum thus making them eminently suitable for deodorization application wherein high quality of open / sparging steam has to be handled.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Silver |

| Country of Origin | India |

| Type | Liquid Eductor |

| Material | Stainless Steel |

| Usage | Lifting, Pumping, Mixing, Agitating Liquids, Handling Granular Solids And Slurries |

| Benefits | Low Cost - Small Units, Low Cost,Self Priming - Operates In Continuous Or Intermittent Service,No Moving Parts - Simple, Reliable, Little Maintenance,Corrosion And Erosion Resistant - Can Be Made Resistant To Handled Liquids/environment,Safe - Can Be Used |

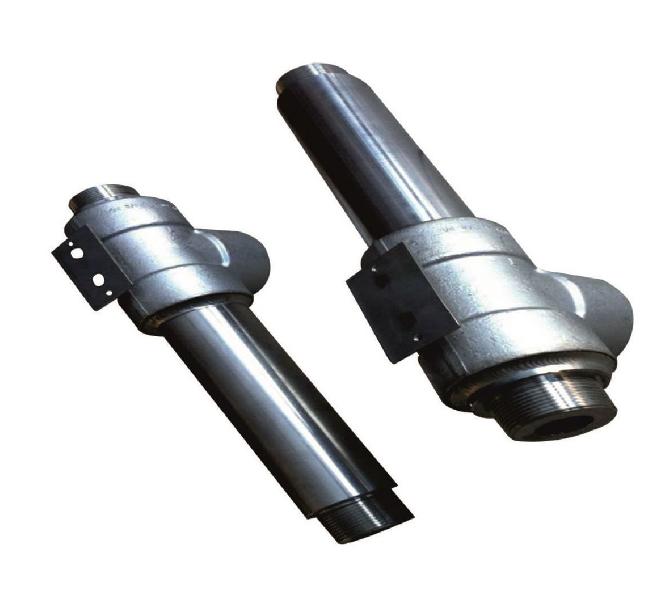

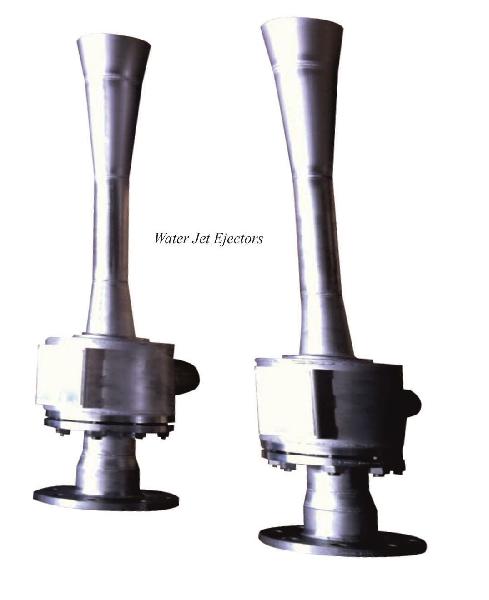

Water Jet Ejectors / Eductor :

- Water jet ejectors (Liquid Eductors) uses water as motive force. Liquid Jet Eductors use the kinetic energy of a motive liquid to entrain another liquid,completely mix the two, and then discharge the mixture against a counter pressure and are used in large numbers throughout industry for pumping and mixing operations.

- Water Jet Eductors consist of three basic components, namely a converging nozzle, a diffuser (or venturi), and a body to hold these parts in their relative positions and to provide a suction (or mixing) chamber. In addition, they can be equipped with accessories such as regulating spindles.

- Water Jet Eductors can also be staged with higher vacuum steam ejectors. In this case, the eductor serves both as the final pumping stage as well as a fairly good direct contact condenser, condensing the motive steam from the high vacuum steam ejectors.

- When designing eductors experience is all-important to correctly design the nozzle, diffuser, and body and their relative positions as they are all highly critical and vary according to the physical properties of the liquids being handled.

- Applications are so numerous, it is impossible to note all of them. General uses include lifting, pumping, mixing, and agitating of liquids as well as handling granular solids and slurries.

Benefits :

- Low Cost - Units are small in relation to the work they do and cost is correspondingly low.

- Self Priming - Eductors are self-priming. They operate equally well in continuous or intermittent service.

- No Moving Parts - Eductors are exceedingly simple and reliabl-e. There are no moving parts to wear or break in a basic eductor. Even when equipped with accessories such as regulating spindles snap valves, float mechanisms, they require little attention, only periodic inspection and maintenance

- Corrosion and Erosion Resistant - Because they can be made of practically any workable material, or coated with corrosion-resistant materials eductors can be made highly resistant to the actions of the liquids handled or The environment in which located.

- Safe - Eductors can be used in hazardous locations where electrically operated alternates would require explosion proofing at considerable cost.

- Versatile - Various piping arrangements permit adapting to environmental conditions. Eductors of vanoustypes can handle granular solids, semi-solids, and slurries without contamination.

- Automatically Controlled - Units can be adapted for automatic control by means of a pressure liquid regulating spindle or a snap-valve and float arrangement.

- Easy to Install - Connections can be made to suit your piping requirements. Little space is required to accommodate units and they are normally so light in weight they can be supported by the piping to which they are attached.

| Business Type | Manufacturer, Exporter, Supplier |

Jet Flow Jet Venturi Fume Scrubber is a dependable device designed to entrain and scrub large volumes of gases without the use of complicated baffles or moving Parts.

The motivating fluid, generally water, leaves the nozzled in a hollow cone spray, creating a draft which draws the gases and vapores into the moving stream where they are continuously scrubbed / absorbed while subsequent separation is accomplished in units specifically designed bny, us to meet the state polution control requirement.

| Business Type | Manufacturer, Exporter, Supplier |