| Business Type | Manufacturer, Exporter, Supplier |

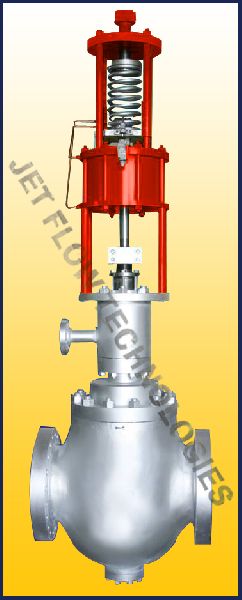

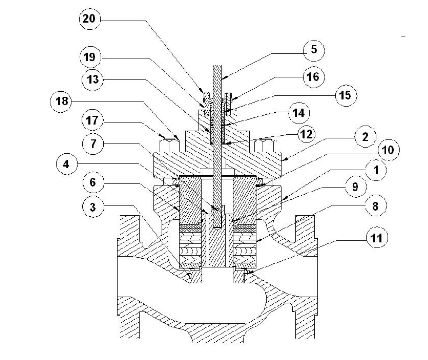

High Pressure Control Valve is designed and developed for applications where the high pressure / drop liquid and high pressure / temperature gas/vapour to be handled. Our specially designed Velocity Control Trim, which is a multi turn / multi-stage velocity control trim, handles these severe/critical applications very effectively – eliminating cavitation & vibration, and reducing the noise to the acceptable levels.

Features:

Velocity Control Trim

ASME B16.34 design standard

Excellent flow control rangeability

Linear, equal % and modified linear inherent flow characteristics

Leakage rate up to Class VI (as per ANSI/FCI 70-2)

Quick Change Trim Design Option

End Connection Styles: Flanged Butt Weld Socket Weld Screwed.

Actuator Options: Spring return diaphragm type as standard, other actuators viz. Electrical, Electro-hydraulic etc as options.

Stem Packings- PTFE for temperature up to 230 Deg. C Graphite for high temperature

Accessories options - Pneumatic positioners, Electro- Pneumatic positioners, Smart positioners, Solenoid valves, Limit Switches, Air Filter Regulators etc. are available.

Plug Options: Unbalanced Metal/Metal Unbalanced Soft seat Direction of Flow: Flowed over

Cv Values and Valve Dimensions - Each valve is designed separately based on the given process data, service conditions and pipe line size & schedule. Cv values and valve dimensions would depend on the required no. of turns/stages, flow characteristics & pressure rating, and decided upon case by case basis. Hence, Cv values are not given in this technical bulletin; they would be specified on the calculation sheet and technical specification sheet of each valve.

Read More...

Features:

Velocity Control Trim

ASME B16.34 design standard

Excellent flow control rangeability

Linear, equal % and modified linear inherent flow characteristics

Leakage rate up to Class VI (as per ANSI/FCI 70-2)

Quick Change Trim Design Option

End Connection Styles: Flanged Butt Weld Socket Weld Screwed.

Actuator Options: Spring return diaphragm type as standard, other actuators viz. Electrical, Electro-hydraulic etc as options.

Stem Packings- PTFE for temperature up to 230 Deg. C Graphite for high temperature

Accessories options - Pneumatic positioners, Electro- Pneumatic positioners, Smart positioners, Solenoid valves, Limit Switches, Air Filter Regulators etc. are available.

Plug Options: Unbalanced Metal/Metal Unbalanced Soft seat Direction of Flow: Flowed over

Cv Values and Valve Dimensions - Each valve is designed separately based on the given process data, service conditions and pipe line size & schedule. Cv values and valve dimensions would depend on the required no. of turns/stages, flow characteristics & pressure rating, and decided upon case by case basis. Hence, Cv values are not given in this technical bulletin; they would be specified on the calculation sheet and technical specification sheet of each valve.

Graph

Looking for "High Pressure Control Valve" ?

Piece