| Business Type | Manufacturer, Exporter, Supplier |

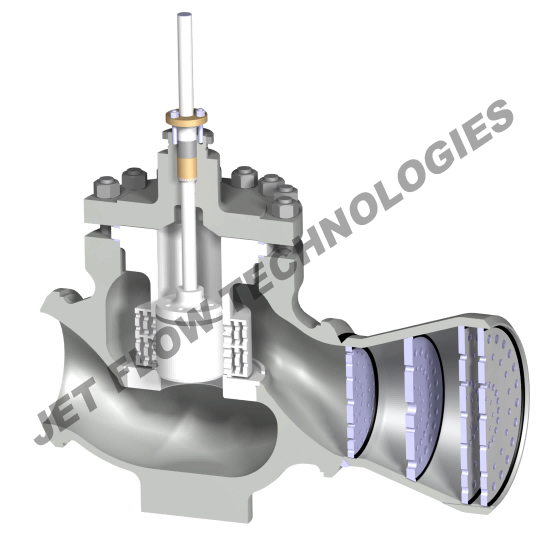

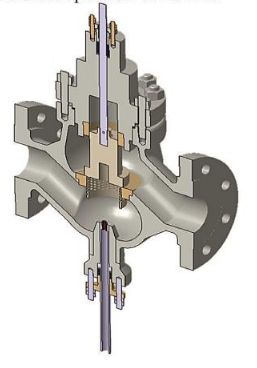

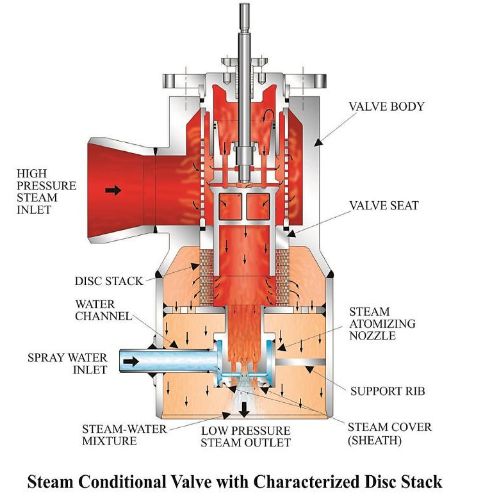

A Steam Conditioning Valve / Combined PRDS Valve is the combination of pressure reduction and temperature reduction of superheated steam to fit process needs, protect downstream equipment or allow the use of less expensive materials or schedules for downstream piping. This is done with a pressure reducing valve and a spray water addition section either as separate units or a single device. Pressure reduction is carried out with a pressure reducing trim within the valve body, usually multi stage pressure reduction. The pressure is controlled by an upstream or downstream pressure controller, signaling the valve to modulate to maintain the pressure at the required set point.Temperature is controlled by adding water to the steam in such away that it will get fully evaporated in the steam, termed as desuperheatmg.

These applications are normally considered to be some of the most severe services of any valves in a modem steam plant.

A Steam Conditioning Valve Jet Flow steam conditioning valve with revolutionary multinozzle atomizer and feed forward design adds to our latest generation of quality valves. The equipment is utilised for simultaneous pressure and temperature reduction of steam. The cooling water is introduced in the highest turbulent zone of the steam. High steam velocity at this point, results in the highest coefficient of heat transfer between the steam and water. The feed forward design assures soft misty spray and instantaneous temperature control over the full range of steam flow.

- For high pressure let-down, pressure drop is taken across concentric flow cages rather than across seating surface, resulting in minimal seat wear.

- Pilot operated cage design to achieve extremely tight shut of (leakage classification ANSI# V)

- Balanced design with heavy duty pilot spring greatly improves throttling stability at high pet?P

- Larger outlet and outlet diffuser options give noise attenuation at optimum design conditions guaranteeing outlets sound pressure level to 85 dBA.

- Stellited trim increases its resistance to corrosion, erosion by abrasion, galling and sticking.

Steam Conditioning Valve Jet Flow steam conditioning valves are available in a variety of combinations. These valves are made as per tailor made requirements of customers. The valves are manufactured in angle, Z and globe forms. Spray water entry is from the top through hollow stem as well as from the bottom, depending upon the process parameters.

Applications are but not limited to:

- Steam Conditioning Valves

- Reheater Valves

- Automatic Re-circulation Valves

- Superheater Spray Control Valves

- Boiler Feed Control Valves

- Start up Steam Vent Valves

- Spray Water Valves

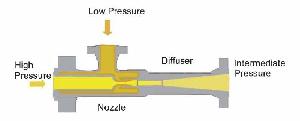

Multi-Stage Multi-Path Pressure Reduction via Velocity Control trim technology:

- Jet Flow Jet Stack trim has stack of discs and each disc is tailor made for a particular flow path that has a variety of features:

- OurJet Stack trim technology uses a series of multi-stage multi-path disc stack for successful operation of our valves in severe service conditions.

The fluid passes through an extremely tortuous path at right angle turns thereby reducing the fluid velocity and therefore reduces the noise and eliminates erosion and vibration problems. The Jet Stack disc stack is tailor-made as perthe requirement of our customers.

The thickness of the wall of Jet Stack trim is such that it ensures maximum tortuous flow path. It ensures the fluid has a uniform velocity and as it passes through the disk it is streamlined. - Its design ensures the flow to be distributed evenly throughout the disc. The open flow channel ensures even distribution.

- Irrespective of flow direction, multi channels are provided. Multi channels evenly distribute fluid around the plug for full stroke thereby ensuring complete control, reliability and stability.

Applications:

- Jet Stack trim has a wide range of applications that demand velocity control and massive pressure drops to be

- catered to across the valve.

- It assists in eliminating cavitation and erosion of the conventional type trim designs, reduces velocity, decreases noise and provides stable control over the entire ?ow range of the ?uid.

Advantage of Jet Flow Steam Conditioning Valvewith Jet Stack Velocity Control trim and laval jet nozzle -

- Series of pressure reducing stages are incorporated in the valve that can go as high as 60 for severe service let down applications. This ensures complete velocity control for the full load with noise levels reduced below 85 dBA.

- Complete tight shut off valve maintaining class V seat leakage.

- High rangeability of 50:1 as a standard is provided, however, higher turn down of 100: [can also be provided upon request.

- Minimum wall thicknesses of the body as per the design conditions to minimize thermal stress and shock.

- Double acting spring return pneumatically operated cylinder piston actuators are provided as a standard. Electric and Hydraulic actuators can also be provided as an option.

- Complete trim assembly is easy to assemble and

- disassemble since no welded designs are incorporated.

- Extremely low maintenance cost with rapid trim

- change over from top.

- The trim has a very long life on account of extremely

- low velocities and with proper use of selected

- materials.

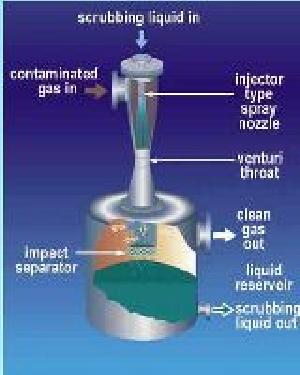

- Laval jet atomizing desuperheater incorporated in the valve ensures no impingement of the water on the downstream piping and thereby no need to install expensive thermal sleeves or liners.

- Substantial savings from the point of installation since the downstream straight length required is extremely short and therefore transition sockets and pipes can be installed very close to the valve.

- Extremely installation friendly. The valve can be installed in either vertical or horizontal direction.

- Spray Water Control Valve -It is of extreme importance that steam temperatures are maintained in utility power plant to ensure safe, reliable and ef?cient operation of the equipment. Spray water control valves are the ultimate control elements for superheaters, reheaters, etc. A ?nely balanced steam temperature control valve will ensure trouble-free maintenance of the equipment for longer runs in a utility power plant.

Requirements -

- Gives the exact quantity of spray water as per the control demand for the entire operating range.

- Valve should be Class-V tight shut-off so that the downstream piping/ equipment are not damaged.

- Should be suitable for higher pressure let down applications without internal damage of the trim.

- Reliable and consistent operation.

Graph 01

Graph 02

Graph 03

Specification

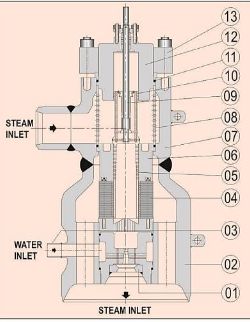

| Bill of Material | |

| Item Description | Material |

| Nozzle Insert | A182 GR F11 / F22 / F91 |

| Body (Lower Part) | A182 GR F11 / F22 / F91 |

| CW INLET | A105 |

| DISC | DIN 1.4122 PLASMA NITRIDED / INCONNEL 718 |

| CONE / PUG | DIN 1.4122 PLASMA NITRIDED / INCONNEL 718 |

| SEAT | DIN 1.4122 PLASMA NITRIDED / A 182GR F11 / F22 / F91 ST |

| MAIN BODY | A 182 GR F11 / F22 / F91 |

| CAGE / INLET CYCINDER | DIN 1.4122 PLASMA NITRIDED |

| STEM | DIN 1.4122 PLASMA NITRIDED / INCONNEL 718 |

| PISTON RINGS | X120 Cr 29 |

| SEALS | GRAFOIL |

| BONNET / COVER | A182 GR F11 / F22 / F91 |

| BONNET / FLANGE | A 182 GR F11 / F22 / F91 |

| ---- | |

| Other grades of material are also used depending upon design requirements. | |