Steam Desuperheaters

Leading Manufacturers, Exporters and Wholesaler of Fixed Area Nozzle Steam Desuperheater, In-Line Venturi Steam Desuperheater, Multi Nozzle Steam Desuperheater and Venturi Steam Desuperheater from Chennai.

| Business Type | Manufacturer, Exporter |

Jet Flow fixed area nozzle desuperheaters are best suited for applications involving minimal load fluctuations. A fixed nozzle desuperheater utilizes high performance fixed geometry nozzles to reduce the steam temperature by directly injecting water inside the superheated steam flow. The water enters the main desuperheater body, passes through the spray nozzles and discharges into the steam line in the form of a fine mist.

| Business Type | Manufacturer, Exporter, Supplier |

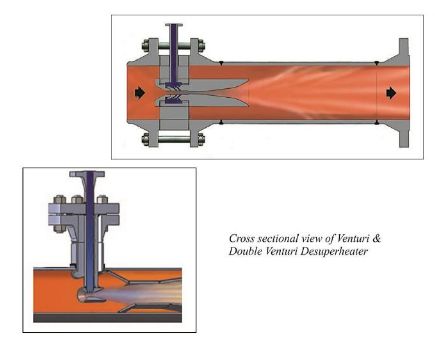

A version of single venturi desuperheater has the same operating conditions. can be mounted easily and quickly in the exisiting pipeline. The unit can be clamped between two flanges. Sizes are between 1 1/2” to 30”

| Business Type | Manufacturer, Exporter, Supplier |

Jet Flow multi orifice desuperheater regulates the amount of injected water by varying the number of orifices during operation.

The ensures that the spray water pressure remains constant at all loads and an excellent and almost uniform spray quality is achieved over the full operating range, thereby minimising the tendency of spray water to accumulate in the steam line.

Opening of the orifices is regulated by the positioning of a piston operated actuator directly mounted on the desuperheater.

This compact and simple design ensures no separate spray water Injection control valve is required.

A high turndown of 50 : 1 is standard.

| Business Type | Manufacturer, Exporter |

Jet Flow venturi desuperheaters consist of a Laval nozzle which utilises a part of the incoming steam flow to create a reduced pressure zone into which spray water is drawn and atomised by steam energy, and then exits in a short expanding throat which allows pressure recovery.

The desuperheating performance remains constant at all loads from 100% or less, because of the atomising steam effect of the steam jet. The design is unique such that the spray water can be supplied at the same pressure as that of the steam pressure. High turndowns are possible depending upon

installations.